Within the ever-evolving realm of fashion, personalization has turned into a central movement. As consumers seek to express their unique selves, bespoke designs and personalized apparel have gained immense fame. A of the most creative techniques shaking things up in this field is DTF transfers, or direct-to-film transfers. This method allows for vivid, detailed designs to be printed and transferred onto various fabrics, providing an extraordinary way to bring unique visions to life.

The craft of custom DTF transfers opens the door to endless artistic possibilities. Whether it's for a small business aiming to stand out or an individual looking to showcase personal style, this technique provides the flexibility and quality needed to create notable pieces that truly embody the owner's personality. From custom dtf transfers to subtle, intricate designs, the journey from idea to closet is not just about creating clothes; it's about telling a story through style.

Grasping Direct to Film Prints

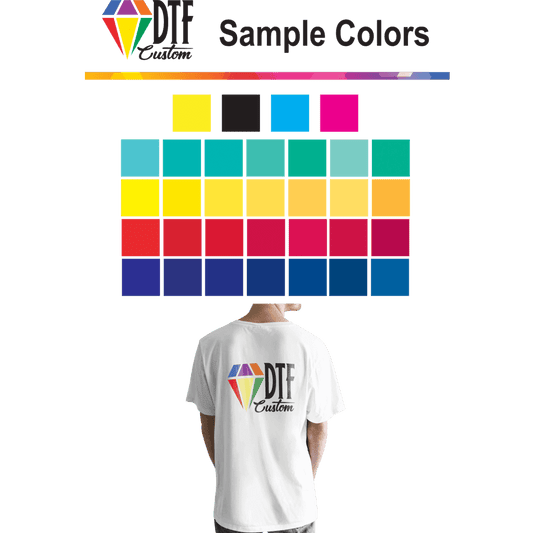

DTF (Direct to Film) prints are an cutting-edge fabric printing method which permits for vibrant and detailed graphics to be applied to multiple materials. This method involves applying a pattern onto a unique transfer material, which is then transferred to the material using temperature and pressure. Differing from traditional approaches, DTF transfers can easily duplicate intricate pictures and vivid shades, making them a preferred option for personalized clothing.

One of the major benefits of DTF transfers is their capability to stick to a wide variety of fabrics, including natural fibers, synthetics, and blends. This versatility makes them appropriate for a variety of items, ranging from t-shirts to hoodies to bags. Furthermore, DTF prints are known for their strength and resistance to breakage or fading, making sure that personalized graphics maintain their vibrancy even after multiple launderings.

The DTF method also highlights efficiency and speed, enabling businesses to generate bespoke designs in limited or big quantities without compromising standard. As more people seek distinctive clothing styles through bespoke clothing, DTF prints have emerged as an vital tool for designers and companies looking to elevate their products in tight markets. spintax

Our Customizing Process

This customization procedure for bespoke DTF transfers begins with the initial concept. Artists or stakeholders present their visions, which can range from intricate graphics to basic text. This first stage is vital as it allows for artistic expression and individual branding possibilities. By exploring elements like shade schemes, themes, and target audiences, the groundwork is laid for a successful transfer.

Next, the professional side comes into play. Designers use specialized software to create digital images that meets the criteria for DTF printing. This includes verifying the design is in the proper format, modifying sizes, and choosing the right colors. The digital file is then prepared for printing, where it's critical to consider aspects such as resolution and detail to ensure a premium transfer. Focus to these details profoundly impacts the final product quality.

Ultimately, the DTF transfer is printed onto a particular film, which is then bonded to the chosen garment. This stage involves precise application techniques to ensure durability and brightness. After printing, the transfer goes through a heat application process, which bonds the design to the cloth. This last step is essential for achieving a professional finish that withstands to wear and washing, making each custom DTF transfer not only a fashion statement but also a permanent addition to any wardrobe.

Applications and Perks

Tailored DTF designs have found a crucial place in the apparel industry due to their flexibility and user-friendliness. Clothing brands can create intricate artworks and bold imagery that can be transferred to a wide selection of fabrics. This versatility makes DTF transfers perfect for anything from urban fashion to designer wear, enabling artists to showcase their creativity without being constrained by the material. They can also be employed for individual endeavors, allowing individuals to modify their wardrobes in original ways.

Another key advantage of tailored DTF designs is their resilience. Compared to some processes, DTF transfers offer a remarkable level of resilience against wear and washing. This durability makes them a smart choice for businesses looking to manufacture merchandise that will keep its appearance over time. The ability to withstand numerous cleaning processes without losing color or breaking ensures that clothing adorned with these prints remains attractive, thus enhancing customer satisfaction.

In addition, the quickness of production with DTF transfers is a notable advantage for both boutique designers and mass producers. The technique allows for rapid turnaround times, allowing brands to adapt promptly to market demands and market needs. This efficiency not only helps in maintaining stock fresh but also minimizes the risk of overproduction. As a outcome, personalized DTF designs shine as a favored option in the dynamic fashion landscape, combining innovation with practicality.